This article is available Open Access via the journal.

A slight detour from my usual environmental chemistry work, this paper was led by PhD student Kate Irvin and looks at characterising PVC samples in an industrial setting, finding ways to optimise the product development process.

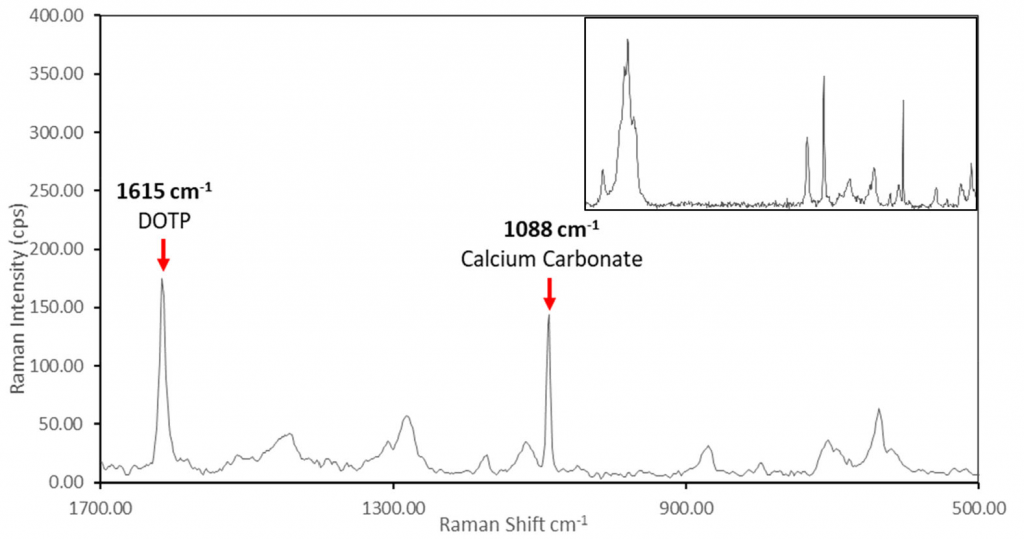

When developing a new polymer product, it is important to regularly test its properties and confirm its ingredients. Typical tests take hundreds of hours and can delay the development cycle, adding costs to the process. In this paper we demonstrate some rapid, non-destructive techniques for quantifying the amount of plasticiser (dioctyl terephthalate) and filler (calcium carbonate) within a PVC sample.

Fourier transform-infrared spectroscopy and Raman spectroscopy were used, since they are quick, easy-to-use and non-destructive methods of identifying samples. The time savings alone of using these methods compared to using traditional hardness, softness and tensile tests could reduce product development costs by 50%.